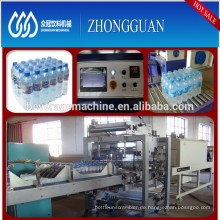

2014 NEW Carton Packing line for Bottled Water

Basisinformation

Modell: ZGC-20

Produktbeschreibung

Specifications

1-Carton Packing line for Bottled Water2-Production Efficiency:8~25 cases/min

3-Nordson Hot Melt

Carton Packing line for Bottled Water

2.Each individual machine parts in terms of user-friendliness and stability when it comes to feed and changeover.

3.The configuration such as PLC transducer, position and axle control are all imported.

4.Applicable to production lined of various bottle types, glass bottles , PET bottles, cans etc.

5. It's equipped with safety guard device to ensure the safety and smooth during the process. The protective door is made up of stoving varnish and acryl,from which operation condition can be seen very clearly.

6.Material: The transmission shaft is adopted S45C, other mechanical parts are made of chromized steel, stainless steel and anodic treatment, anti-rust aluminium

7.The entrance conveyor is adopted low friction coefficient plastic steel chain net, together with a leading bottle device to ensure bottles to entry smoothly and successively.

8.Self adjust speed function. It adopts detecting switch and muturly connected device, which can detect and adjust the operationg condition automatically during the whole prodction line.

9 .Detecting device of bottle falling is equipped at the entrance of conveyor to the host machine in case of bottle falling or missing.

10.The carboard supply is set below the bottle entering conveyor, which can hold 800~1000 carboard (Slot loading style)

11.The carboard separation is adopted vacumn sucker device.

It adopts carboard detecting device on the slope of feeding paper.

The continous operating wrapping device can be adjusted at one place, that is adjusted through location detector according to different carton size.

The host electrical cabinet is set on the host machine.

There is ventilation device in the host electrical cabinet.

Mobile operation board.

The operation board is adopted touch-and-control human machine connector, which is connected with PLC in the host electrical cabinet. It can provide:

Modifying the operating parameters, and store different packaging data;

Detecting production condition

Storing operation condition

Monitoring working condition instantly

1-Automatic Wrap Around Carton Caser for Bottles

2-Production Efficiency:8~25 cases/min

3-Power:11.47KW

4-Bottle Conveyor Height:1100+-50mm

5-Box Conveyor Height:1100+-50mm

6-Application: Bottles/Cans/Various kinds of container

7-Carton Material:corrugated paper

Produktgruppe : Flaschenverpackungsmaschine

Premium Related Products